Accelerated Sedan Development and Halved Defect Rates

For a Car Manufacturer

Partnering with EVTS was a turning point for our new sedan line. Their thorough engineering and testing framework helped us reduce our prototyping time by 30% and cut overall defect rates in half.

Throughout the process, their experts were always available to provide clear guidance, ensuring we stayed on schedule and delivered a higher-quality vehicle. We truly value their dedication and look forward to future collaborations.

Battery Cost Savings and Higher EV Efficiency

For an Electric Vehicle (EV) OEM

We collaborated with EVTS to optimize the design and performance of our latest electric SUV. By integrating AI-driven analytics and IoT-enabled monitoring, we were able to reduce our battery development costs by 20% and improve energy efficiency by 15%.

EVTS’s commitment to our vision of sustainable mobility was evident at every stage, making this partnership both smooth and highly productive.

Streamlined Scooter Production and Reduced Assembly Errors

For an Electric Scooter Manufacturer

EVTS provided the automation solutions we needed to enhance our urban electric scooter production. Their real-time monitoring dashboards helped us identify and eliminate bottlenecks, resulting in a 25% boost in daily output and a 40% drop in assembly errors. Their responsiveness and clear communication made all the difference, and we couldn’t be more grateful for their support.

DataCenter Transformation

For a Leading Energy Sector Enterprise

We successfully discovered and migrated over 18 workstreams to Google Cloud, covering both databases (Oracle, BD2 ) and applications, including monolithic and microservices architectures. Post-migration, application teams can now adapt to fast-paced go-lives, and the customer can easily scale infrastructure to meet evolving business needs. Data warehouse modernization has unlocked advanced analytics capabilities and paved the way for future AI/ML initiatives. Application modernization has also become more seamless, enabling development teams to operate more efficiently , improving productivity by 42% with minimal infrastructure disruptions.

Extended Service Intervals for Semi-Truck Reliability

For a Semi-Truck Manufacturer

Working with EVTS allowed us to elevate the durability and reliability of our new semi-truck series. Their advanced automation techniques and predictive maintenance models extended our service intervals by 10% and lowered our repair costs by 18%.

We were continually impressed by their hands-on approach and thorough technical expertise, which contributed directly to our project’s success.

Sharper Drone Performance Through Data Analytics

For a Drone Technology Developer

We specialize in drone technology for both industrial and consumer markets, and EVTS was instrumental in refining our flight control algorithms. With their data analytics support, we shortened our iteration cycles by 40% and achieved more stable flight performance overall.

The EVTS team showed genuine enthusiasm for our product, and their solutions far exceeded our initial expectations.

Textile Facility Productivity and Energy Use Transformed

For a Textile Plant Automation

When we decided to modernize our textile facility, EVTS stepped in with an Industry 4.0 framework tailored to our needs. By introducing robotic systems and machine-to-machine communication, we saw productivity climb by 35% in the first quarter alone, alongside a 20% reduction in energy consumption.

We deeply appreciate their guidance throughout this transition—it made a world of difference for our operations.

Cloud Migration Success and Reduced IT Maintenance Costs

For an IT Infrastructure Company

As a provider of IT infrastructure, system reliability is crucial for us. EVTS assisted with our multi-cloud migration and set up robust disaster recovery protocols, bringing our uptime to 99.98% within six months. We also achieved a 25% cut in server maintenance costs.

Their willingness to truly understand our requirements and offer tailored solutions was impressive, and we look forward to working with them again.

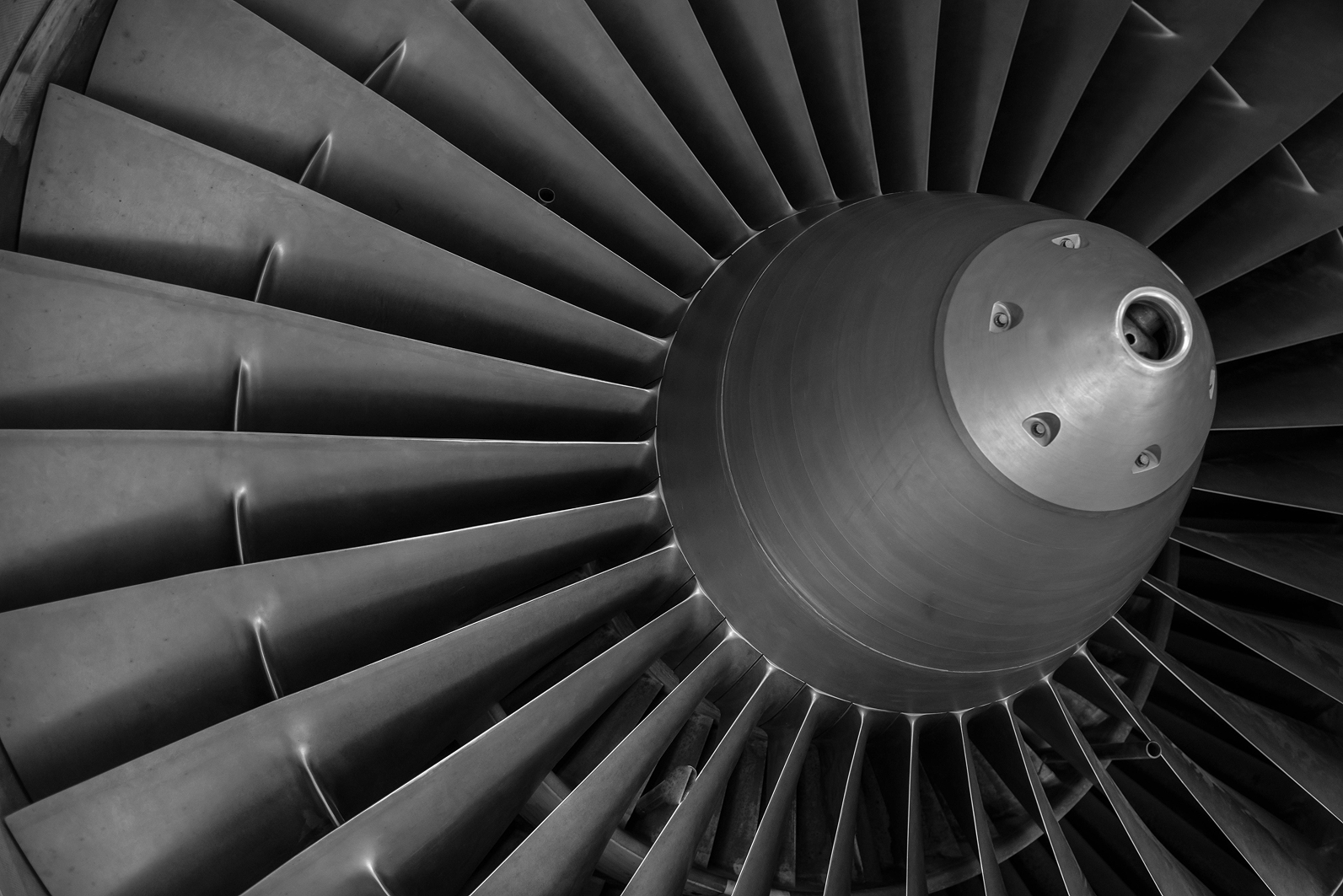

Precision Engineering for Aerospace Components

For an Aerospace Components Supplier

Precision is paramount in aerospace, and EVTS helped us fine-tune our components for satellite systems. Their engineering insights and data analytics support enabled us to improve part tolerances by 15% and speed up our quality inspection process by 30%.

We’re grateful for their close collaboration and the genuine care they demonstrated for our unique requirements.

IoT-Driven Harvest Efficiency for Farm Machinery

For an Agricultural Machinery Manufacturer

We approached EVTS to integrate IoT-based monitoring into our harvesting equipment. They introduced predictive analytics that immediately reduced machine downtime by 25% and boosted harvest efficiency by 10% in the first season.

Their consistent support and expertise helped us adapt new technologies seamlessly, and we couldn’t be happier with the results.

Migration & Modernization of Large SQL Server Clusters

For a Leading logistics Enterprise

We migrated a large-scale 138-VM SQL Server cluster to Google Cloud, leveraging a Bring Your Own License (BYOL) model to utilize existing licenses and avoid dual costs. The migration preparation, testing, and execution were automated using Terraform and PowerShell scripts, accelerating the process by 63%. Multiple interconnects were configured to support high-volume data synchronization. As part of the modernization program, we ensured 100% data integrity and fidelity with zero downtime. Strategic offshore resourcing helped achieve a 56% cost reduction in migration efforts.

Warehouse Robotics Refined with Intelligent Automation

For a Warehouse Automation Provider

We develop automated warehouse solutions, and EVTS elevated our robotics platform with intelligent automation workflows and Agile development. By refining our software and hardware integration, we lowered our overall software bugs by 35% and kept the project timeline firmly on track.

We sincerely appreciate their personal commitment to our success—our clients have already noticed the improvements.

R&D and Process Automation

For an EV Battery Manufacturer

Our company focuses on electric vehicle battery manufacturing, and we were looking to accelerate our R&D processes. EVTS set up automated testing rigs, AI-based failure detection, and live reporting tools that cut our prototyping phase by 20% and boosted our battery’s energy density by 18%. We were impressed by how seamlessly their solutions fit into our existing setup.

EVTS’s personalized approach and dedication to cleaner transportation made all the difference.

Route Optimization & Fleet Management

For a Logistics Company

We operate a regional logistics and delivery service, and our route planning was highly manual and prone to scheduling inefficiencies. EVTS helped us implement an automated fleet management platform featuring AI-based route optimization and real-time vehicle tracking. Almost immediately, we cut fuel costs by 20% and improved our on-time delivery rate by 15%. Our dispatchers now have a clear overview of every driver’s location, enabling them to adjust routes on the fly.

Thanks to EVTS, we’ve seen a tangible boost in both customer satisfaction and operational savings.

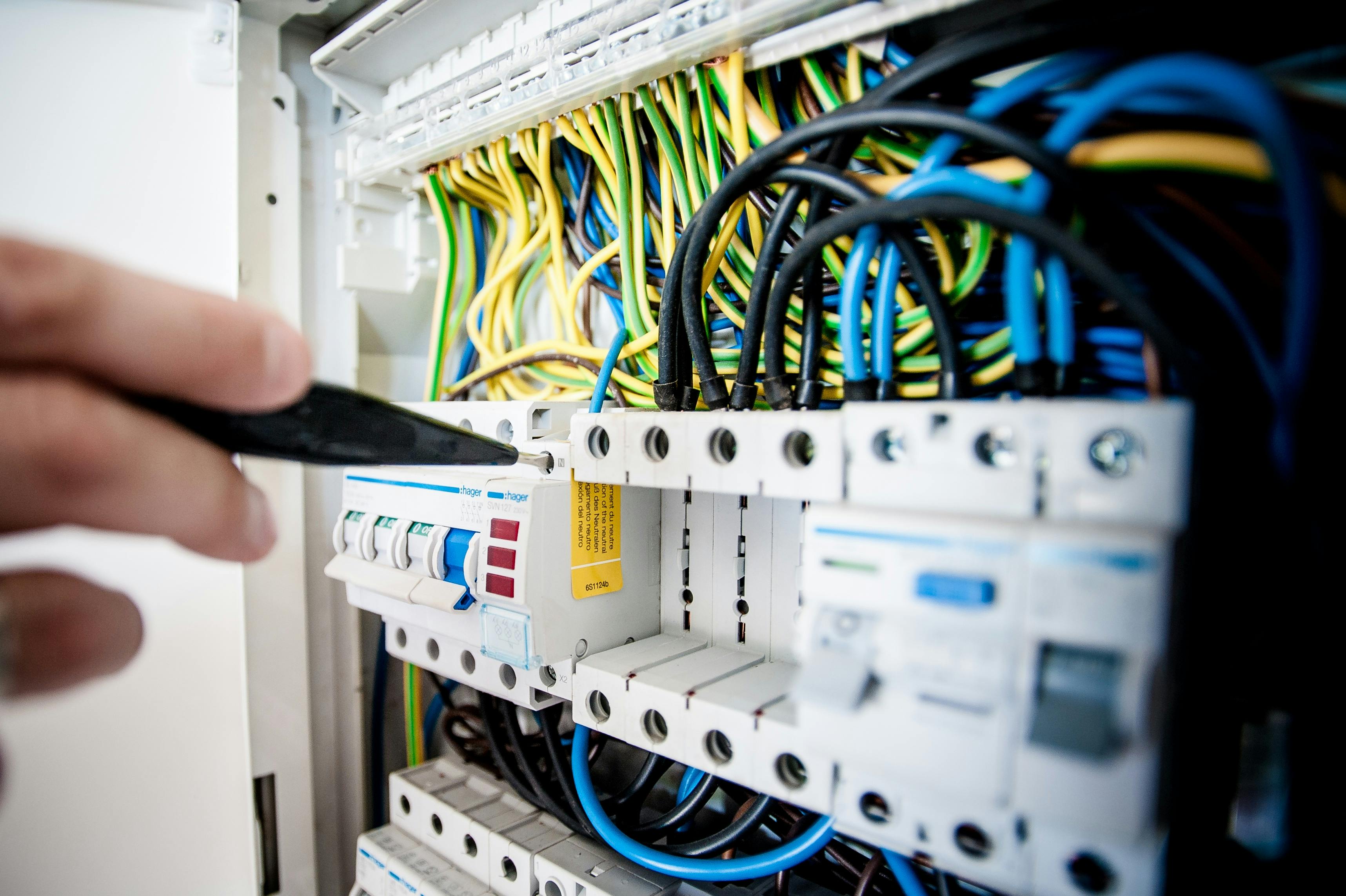

Work Instructions & SOP Implementation

For a Wire Harness Manufacturer

Our facility specializes in producing complex wire harness assemblies for various industries, and we faced recurring challenges in maintaining consistent quality and timely production. EVTS guided us in overhauling our SOPs, from color-coding standards to assembly checklists, and introduced a digital platform to keep instructions up to date. Within three months, we saw a 25% drop in assembly errors and trimmed our production cycle times by nearly 20%. Our teams have reported greater clarity and fewer rework requests thanks to the standardized instructions.

EVTS’s meticulous approach to detail and user-friendly documentation truly elevated our manufacturing process.

Contact

GET in Touch

Presence

India, USA

Cities

Jaipur, Pune & Michigan

Email Us

info@enervoltiq.com

.png)